The Chilean fruit industry plays a key role in the global market and will be increasingly challenged and pressured for the proper use of natural resources, sustainability and safe food. The use of water in cherry sorting and packaging processes is an area where there is room for improving water use and also for more efficient use of post-harvest treatments that are safe for the consumer.

Each cherry producing and exporting company present in our country creates different work guidelines in order to guarantee the food safety of its processes at all times. In the particular case of cherries, and considering that the vast majority of sorting machines use water as a vehicle for transporting and treating the fruit, the challenge will focus precisely on the ideal design of a work guideline that pursues the rational use of resources and the effectiveness of the treatment.

With this focus, TECNIDEX developed and validated two technologies: CONTROL-TEC DOSIFIER – CONTROL-TEC ECO.

CONTROL-TEC DOSIFIER is a proportional fungicide application system with intelligent dosing control, capable of adjusting the scheduled delivery of products according to the volume of fruit processed or the volume of water consumed during the process.

CONTROL-TEC ECO is a continuous filtration system for process water. The constant recirculation of the prepared solution, combined with the use of filters specially developed for post-harvest use, allows for the extension of the use of broths and the economy of the use of fungicides, since it allows the recovery of the active ingredient by separating it from the organic matter.

A successful case study.

Together with Mr. Ramón González B., Quality and Development Manager, Exportadora Rio King and the group of professionals who work under his direction, it was possible to demonstrate excellent results with the use of TECNIDEX technologies. The set of CONTROL-TEC DOSIFIER equipment added to the CONTROL-TEC ECO filtering system demonstrated the capacity to recover the active ingredient of fungicides from the process and also the saving of water by achieving an extended use of the prepared broths while maintaining their food safety.

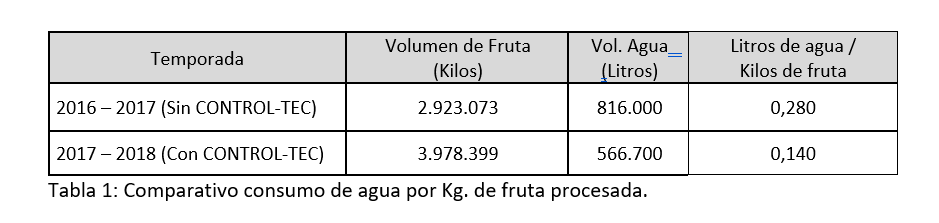

The results in Table 1 consider a comparison of the water consumption obtained during the 2016-2017 processing season without the use of TECNIDEX technologies in contrast to the 2017-2018 season where said technological proposal was implemented.

It is possible to observe that, although there was an increase of 36% in kilos of processed fruit during the 2017-2018 campaign, the water consumption ratio per kg. of treated fruit decreased by 50% when compared to the previous season, falling from 0.280 L/kg to 0.140 L/kg.

Associated with the evaluation of water consumption, the consumption of fungicides in the processes when using the filtering system was also evaluated, since by prolonging the useful life of the solution, the consumption of fungicide should decrease.

The results in Table 2 show the total volumes of fungicides used during the last two seasons and the volume of fruit processed. Although one of the fungicides was changed, a direct comparison can be made with fungicide A, which was used at the same rate both seasons:

The results in Table 3 compare the volume of fungicides needed to process 100 Kg of cherries in both seasons. A difference of approximately 35% less fungicide (A) can be seen to process the same volume of fruit in the 2017 season, so by prolonging the shelf life of the fungicide a considerable decrease in its consumption is achieved.

The results obtained during the validation of CONTROL-TEC technologies in the cherry processes of exporter RIO KING, demonstrated:

1.- Saving 50% of water by extending the use of prepared fungicide broths without sacrificing their effectiveness and maintaining food safety.

2.- Reduce fungicide consumption in the order of 35%, the extension of use of the broths translates into reducing replacement frequencies.

3.- Reduce the cost of the fungicide program in the order of 50%, as a result of the consumption decreases expressed in points 1 and 2.

4.- The positive economic results achieved with the savings of the different elements demonstrated in the present study and those that were not considered, but are implicit in it, such as electric energy, man hours, among others, lead us to conclude that the rate of recovery of the investment is high, allowing its accelerated implementation in the different critical points of the process, achieving the enjoyment of its benefits from the first year of work, further improving the consumption and efficiency ratios of the described process.

5.- This information should be considered valid for the process and experience described and will be used only as a reference to evaluate its implementation in other companies and production realities. Do not hesitate to contact us to carry out a technical survey and pre-evaluation of the investment.