The future is already here and it is brought to you by Diagnofruit.

Since the recent pandemic, techniques based on molecular biology are no longer unknown tools. The general population has used them, talked about them and at the same time understood that the future of diagnosing diseases in humans, animals and plants is based on this type of analysis. For a long time, the natural order of development of this type of innovations was born in human medicine, then they move on to veterinary medicine to end up in phytopathology. Certainly, today these gaps and times are much less noticeable, because knowledge is more massive and costs are lower than what existed until a couple of decades ago. Diagnofruit, a leading company in plant disease diagnosis, began in 2016 to transform and adapt knowledge to innovate in the detection and quantification of plant pathogens through qPCR. Today, after a path not without challenges, it has launched one of the services with the greatest impact in the cherry export industry, which aims to reduce the risk of fruit rot, generating a sustainable industry with a long-term view, promoting a high-quality product.

To learn more about this local technological advancement, we spoke with Hector Garcia, co-founder of Diagnofruit Laboratories Ltda., and one of the creative minds behind this service.

How did this idea come about and what pain points did you see in the industry in driving the development of the service?

From my previous work in export companies, I know that the opportunity to have information is very relevant for decision-making and within fruit production, predicting diseases, in this case directly related to the product to be exported, fruit rot, is absolutely relevant to generate a product that encourages a second purchase. An example of this is what happens to us with Peruvian avocados, we know that they brown and rot very easily, therefore, I do not buy them again or I try to buy them only if I have no alternative; well, with Chilean fruit we do not want that to happen. In general, in the laboratory we have techniques to know if a fruit has a short post-harvest life, but they are time-consuming, space-consuming and labor-intensive. So, we had a real need to know how much inoculum we had in the fruit or in the packing lines and that traditional prediction systems were not able to address, especially in a fruit like cherries that have an extremely short cycle; that is how the idea was born, through a real industry need.

I imagine that the beginning was not easy, how did you manage to establish the foundation to develop the technique, funds, advanced human capital?

Yes, it is complex, especially almost a decade ago, when molecular techniques were not widely used. We were awarded a grant through a competition CORFO (17CH-83909) which allowed us to hire the Dr. Analia Espinoza to develop the first objectives, in two years of study. The project was entitled: "Determination of the degree of latent infection of Botrytis cinerea and Geotrichum candidum in orchards, fruits or packing during production processes in stone fruits" so we began exploring, and today we end up with a much more versatile service than initially planned.

Considering what you're telling me, how has the technology evolved from the project prototype to how it is sold today, as an integrated service to the industry?

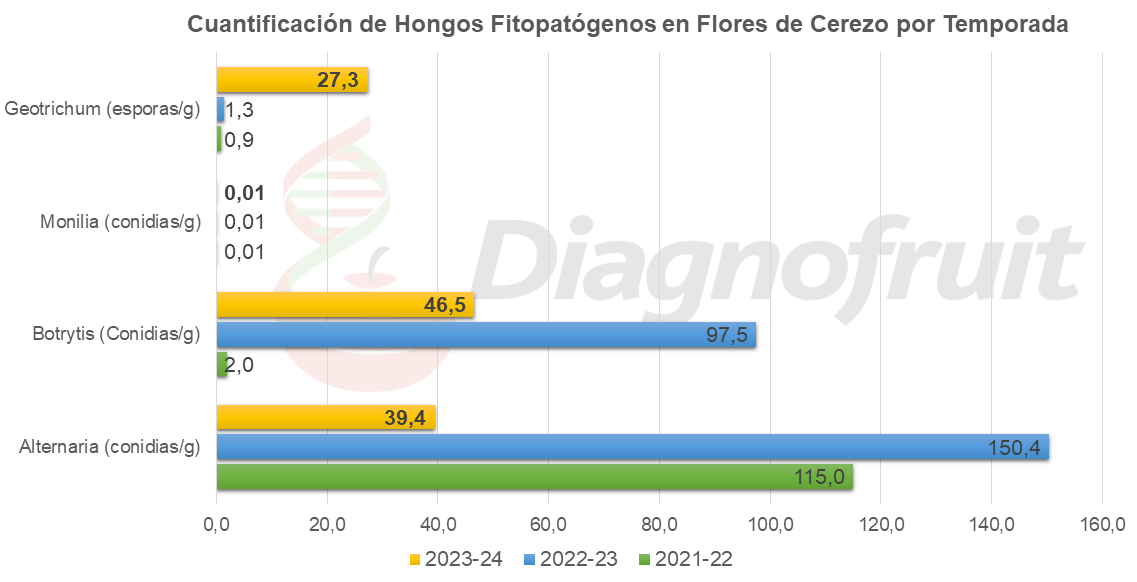

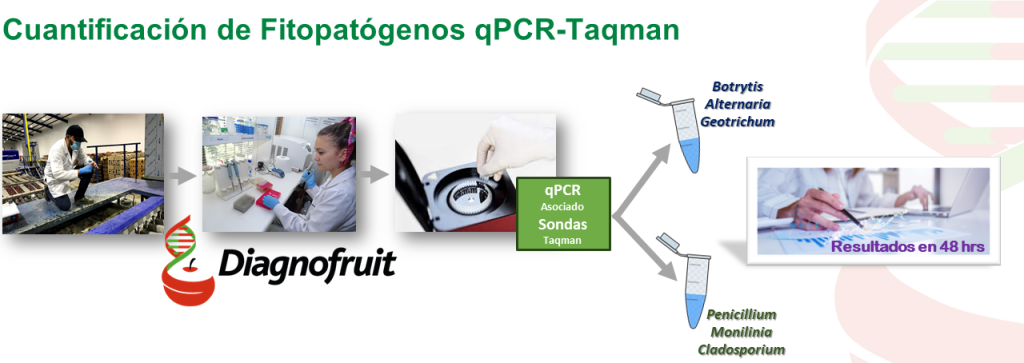

The first thing was that as the seasons went by we saw the importance of other pathogens in the case of cherries, so we integrated Alternaria and Penicillium into the standard model, with the possibility of quantifying other fungi such as Monilinia and even bacteria such as Pseudomonas, obviously no longer considering the possible generation of rot in the latter case, all this goes hand in hand with the possibility of building risk thresholds. The second was to move towards cheaper systems without reducing precision, so we entered the world of multiplex qPCR associated with the use of probes, which allow us to establish the quantification of several pathogens in the same sample tube, which also makes a faster diagnosis. We work in unison on more efficient DNA extraction methods, we copy “machines”, we even use 3D printing to generate some instruments that facilitate the process. As this had to be very fast, we had to have high confidence in the result. Although we had biological and technical replicas, we added several controls that ensured that the system was working and the report delivered had a high degree of reliability. This whole part has been largely developed by our Technical Manager, Dr. Miguel Lopez, who today also directs our activities in Colombia.

Who are your clients?

The main clients for this service are fruit processing plants, and to be more precise, exporters hire this service more frequently. Another level of sales is through companies that establish these analyses as part of their post-sale service. In this way, we have a program with PACE Chile, where they monitor their own clients and ensure the optimal functioning of their sanitation systems. In pre-harvest, exporters to know the risk of the various producers and agrochemical companies that use these methods to know the impact of control treatments are the main users of this service.

Well, and most importantly, how does this innovative diagnostic service work?

In summary, samples are taken in the field (flowers or fruits) or in packing (water or surface swabbing), and they are taken to the laboratory during the day. The samples are processed within 24 hours of their arrival, we extract DNA, and then we continue with the qPCR protocol, for which we have groups of pathogens for simultaneous analysis. Strictly speaking, two qPCR processes are carried out for each sample, and up to 3 species can be quantified in each tube; this simultaneity is achieved with the use of Taqman probes. The results are sent between 24 and 48 hours; and in cherries we have risk thresholds for the most important pathogens in water contamination and epiphytic populations in fruit. There are certain critical points to consider, for example, straw color is a good time to quantify epiphytic populations of fungi that cause rot.

The qPCR is a variant of the PCR, which allows us to detect and quantify DNA, in this case of a target phytopathogen. For example, if I want to quantify Botrytis, it tells me how much DNA of this fungus there is in a sample, and according to a standardization that we carry out in the laboratory, we know that a quantity of DNA represents a number of conidia and that is the number that we deliver. At the same time, we have observed that there are critical population levels, but exceeding a certain threshold the probability of finding rot increases, so we build a basic diagnosis. But sometimes it is impossible to generate thresholds, or very difficult, for example, on surfaces of the packaging line, refrigerator, so what counts in that situation is the history, pre- and post-sanitization sampling, they tell us if this important management works or not.

What are your projections and challenges for the service in the coming seasons?

Last season we carried out more than 3,000 samples from cherry packing alone, and about 1,000 from stone fruit processing; to these numbers we must add the pre-harvest analyses. We still have room to grow and the idea is to at least double the number of analyses. Today, the country's main exporters use the service constantly, so probably more than 60% of production, in terms of processing plants, goes through our analyses; but there are smaller companies, which we only started serving last year and that is where we will prioritize integrating this season.

In technical terms, we are working on other fruit species, for which we are in the process of developing detection of other pathogens, one of them being Geotrichum citri-aurantii, a real headache for citrus producers, often more damaging than Penicillium. We also have our eyes set on flower production in Colombia, that is the great short-term challenge.

In short, we still have great challenges ahead of us. We understand that the speed of response is what makes us different from our competition, so we are always evaluating how to improve our processes, always focused on our clients achieving sustainable production.

Users tell us about the use of the service

For ANASAC efficacy studies, is it useful to have tools for quantifying phytopathogens in the field? What has been your experience?

“Absolutely, today it is a basic tool for understanding the control of phytopathogens in the field. In the case of population dynamics, it is very useful for putting together the strategy. And in the case of infection levels, it allows the strategy to be validated (effectiveness of what has been applied).”, said Simon Navarrete J., Head of R&D, Fungicides and Biofungicides Line, Anasac Chile.

Directly, in your processes as a company, packaging, even marketing, how important is the use of pathogen quantification technology through qPCR for Greenvic today?

“The technique gives us results very quickly and this factor has helped us in a complex year with spring rains that, in the case of stone fruit, left a lot of Geotrichum inoculum in the fields and obviously potentially contaminated lines. The fast and precise response allowed us to develop ad-hoc sanitation strategies in order to reduce the risk; in this way, the service becomes a key piece in the future as a monitoring tool in packing,” explained Eduardo Godoy V. | General Quality Manager. Comercial Greenvic SA

How do these types of high-tech services fit in with the sanitization services offered by PACE? Are they important?

“Extremely important, the quantification by qPCR associated with probes helps to give the client peace of mind, in some way ensuring that their fruit will not have any problems with the most important rots; this is a biological alert system that is coupled with the monitoring carried out by the machines and thus ensures that we generate a complete after-sales service for our clients. In addition, this tool helps us to obtain data on the different fruit processes, considering that it receives information or fruit from different areas, which helps us to make decisions on the technical strategy for the season,” said Cristobal Avila, Product Manager-Latam. PACE Chile

What is the usefulness and importance, for DOLE processes, of using the phytopathogen quantification service through qPCR in cherry and stone fruit packing lines?

“We have several automated monitoring systems in packing, which, for example, control chlorine and pH at optimal levels; however, the data that really closes the system is whether or not there are living microorganisms, including fungi such as Botrytis or Geotrichum that can contaminate healthy fruit. So this service comes to close that uncertainty, giving us alerts if common strategies are not working; for example, this season we had to generate ad-hoc strategies due to the greater amount of inoculum that we already quantified in the field, therefore, it is a very important tool, which we adapt better to our processes every year.«, Pamela Donoso R., Technical Manager for Cherries and Pears, explained Dole Chile SA

¿How do you think Diagnofruit helps farmers develop in the short and medium term?

“At Syngenta we have several programs developing solutions to offer sustainable disease management considering the constant dynamics of pathogens that we are facing in the field. In this sense, we have relied on the Diagnofruit team to determine the appropriate positions and uses in the field and post-harvest, to offer a successful program that ensures the arrival of our Chilean fruit to its destination in excellent condition,” concluded Fiorella Gattini, Development Manager at Syngenta Chile.