But this “catching up” must be done responsibly, taking into account all the technical background of product mixtures, considering their formulations, modes of action, pH of the solution, reactions between active ingredients and the behavior of the plant in relation to the products, especially when they are hormonal products.

The following article presents the three components that make a product application successful and that should be reflected in the annual application programs for our crops.

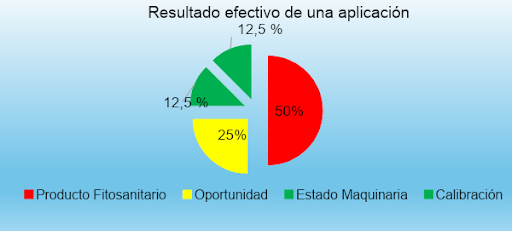

The quality and effectiveness of applications depend on three components (Figure 1).

Figure 1. Responsibility of the factors in the effective control of an application.

Avium 2023 Images.

Taking into account the three components that make a successful application of agrochemical and/or biological products-extracts, plus the accumulated experience on the biology of our crop (development stages), plus the accumulated experience on the biology of pests and diseases that affect our crop, plus the accumulated experience on the agro-climatic and soil conditions of the various production areas of our crop, plus the demands of our fruit customers in terms of quality and condition requirements, we can generate programs that lead us to the success of our crop. This is summarized in our annual application programs for our crop.

In addition to all of the above, we also have the accumulated experience that our fruit producers have regarding the operations they require in the field. We have various application technologies available and we also have ongoing annual training for people who are dedicated to the application function, who are duly qualified and have the relevant safety elements to develop applications in the field.

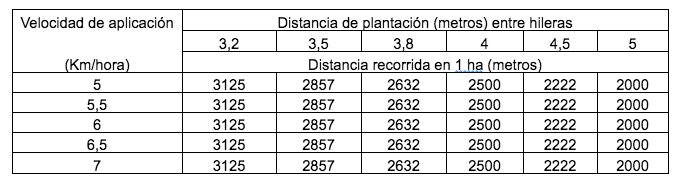

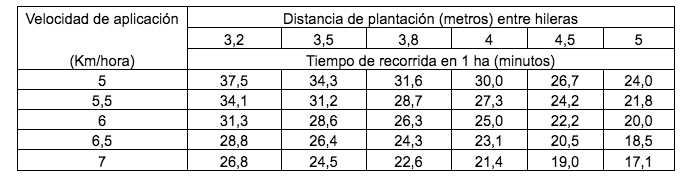

To achieve adequate and efficient work in the field, we can add some data on the time spent on applications expressed in minutes necessary to achieve effective, efficient and standardized applications.

Table 1: Distance covered in 1 ha according to the planting distance between rows (meters).

Table 2: Estimated application time per ha according to planting distance between rows (minutes).

This information can be useful for scheduling our applications during the season, however, there are always “unforeseen events” that occur in fruit growing, such as mechanical breakdowns, absence of personnel, changing weather conditions, availability of products in a timely manner, among other “unforeseen events”.

All these situations are a reflection on the excellent second part of the article in collaboration with Mr. Gonzalo Pezoa, technical manager of the exporter MAGNA.

If there is anything that this complex season can leave us, it is to learn the risks that come with the concept of “catch up”.

This widely used concept was more common than usual this season, where the need to cover emergencies forced us to leave behind previously coordinated applications.

This caused the 7-day or 10-day scheduled programs to be cut short and left with 1 or 2 days of distance; this occurred in all species and with all types of products (insecticides, fungicides, foliar fertilizers, hormonal regulators, etc.), which is very tempting to combine applications and thus optimize the use of machinery,

But this “catch up on”It must be done responsibly, taking into account all the technical background of product mixtures, considering their formulations, modes of action, pH of the solution, reactions between active ingredients and the behavior of the plant in relation to the products, especially when they are hormonal products. Even if it is not a direct pond mixture, this background must also be considered when we apply with 24 or less hours of difference on the same orchard.

Thus, in the case of hormonal products, to avoid damage we must take care of the cumulative effect on the plant; in terms of foliar fertilizers we must take care of the concentrations of salts on fruits and leaves; in terms of insecticides and fungicides, the formulations (EC, WP, EW, SC or WG) all behave differently, both in pond mixtures and in their cumulative effect on tissues, and they take on a predominant role. We must also consider whether the products used have copper, phosphorus or zinc in their composition.

This is why, no matter how much urgency we have, catch up, it is necessary to take a step back and look more broadly at what we are going to do and consult the technical departments of the chemical companies to see if they have experience in the specific mixture we want to make; we must find out how many days or hours must pass before reapplying it to the recently treated orchard.

Most chemical companies, some distributors and technical departments of consultants or exporters have a quick answer, in other cases they have to review it or make the mixture themselves, but what cannot happen is that we make the mixture blindly and see what happens, it plays with the integrity of the fruit and the orchard, many times with immediate consequences and economic damage and other times with invisible damage, which takes its toll on us 1 to 2 seasons later.

Damage such as:

-Edge burning

-Curling of the leaves

-Pitting on leaves and fruits

-Chlorosis on leaves

-Early defoliation

-Russet in fruit

-Damage to pedicels

-Stains on the fruit

-Deformities

-Low floral return

-Excess of vigor

-Fruit abortion

The damages mentioned above, among others, are the most common when making a wrong decision in this rush to catch up.