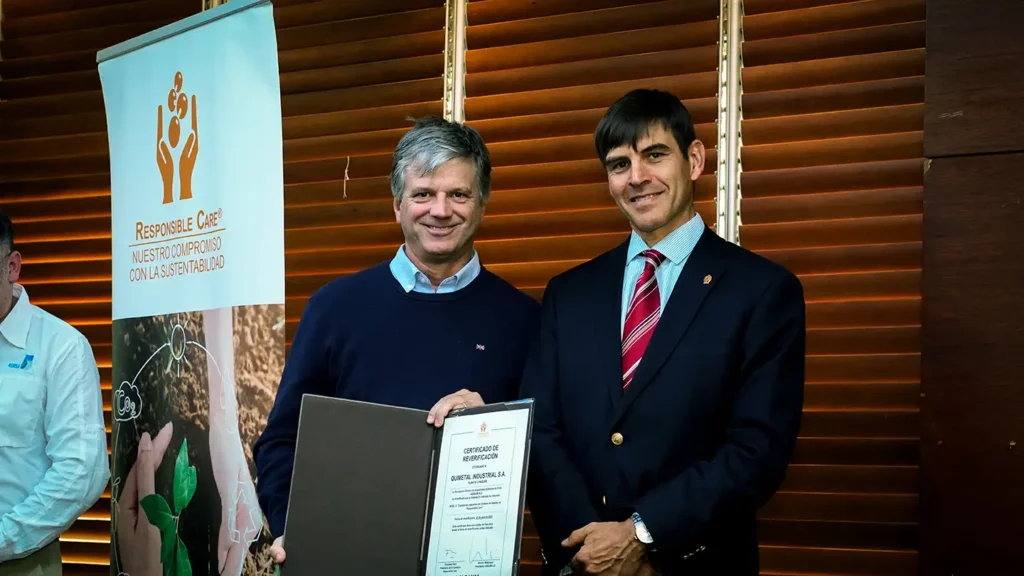

By Francisca Barros B, Jessica Rodríguez F, Militza Ivelic K/ Trío Kimün.

Modified atmosphere technology (MAP) has been a post-harvest tool that has helped preserve the shelf life of this fruit and allowed it to successfully reach distant markets such as the Chinese market.

MAP consists of altering the composition of the internal atmosphere of gases (oxygen and carbon dioxide) within the packaging, either actively (by incorporating gases) or passively through the product's own respiration.

The atmosphere generated inside the packaging will depend on the characteristics of the film used, the product being packaged and the environmental conditions to which it is subjected. In the case of cherries, the use of this technology has allowed the shelf life of the fruit to be extended, which has resulted in greener and fresher pedicels (mainly due to higher humidity levels inside the bag), maintenance of organoleptic characteristics and a reduction in the risk of rot.

When deciding which MAP packaging to use, it must be taken into account that cherries are non-climacteric fruits with a moderate respiratory rate (10-20 ml CO2/kgh at 5°C). The films used for this fruit must be designed based on this information, and their permeability to O2, CO2 and water vapour must be such that the thermal fluctuations to which the fruit may be subjected are taken into account, especially at the destination, where optimal cold chain management conditions do not yet exist. At this point, it is essential to maintain the aerobic condition of the fruit to avoid fermentation problems. The gas concentrations that are sought to be obtained taking into account the aforementioned reality are 10-15% of O2 and 5-8% of CO2.

When using this technology, several aspects must be taken into consideration to achieve the desired objective. Among these key points are:

- The quality and ripeness of the fruit.

- Cold chain management from packaging to the destination of the fruit, with critical points being the temperature of the pulp at the time of sealing the bag (up to 8°C is used to avoid condensation) and the temperature of loading into the container (not higher than 0.5ºC since the temperature in the container is only maintained).

- Sealing the bag to ensure the creation of the atmosphere.

- Setting the temperature and opening of the container's vent. In this last point, the need for ventilation of the container must be considered to ensure the entry of oxygen and the exit of CO2, otherwise strange odors and flavors may be generated due to alteration of the atmosphere. MAP bags were developed to operate in an environment with normal air concentrations.

In our country we have national suppliers that have developed and innovated in the supply of packaging, as well as foreign companies that have local representatives. In the last two decades, the main packaging used with this technology for cherries is 5 kg bags (most commonly used packaging) and 2.5 kg bags.

The main considerations to take into account when choosing the bag to be used are the following:

- Bag dimensions:

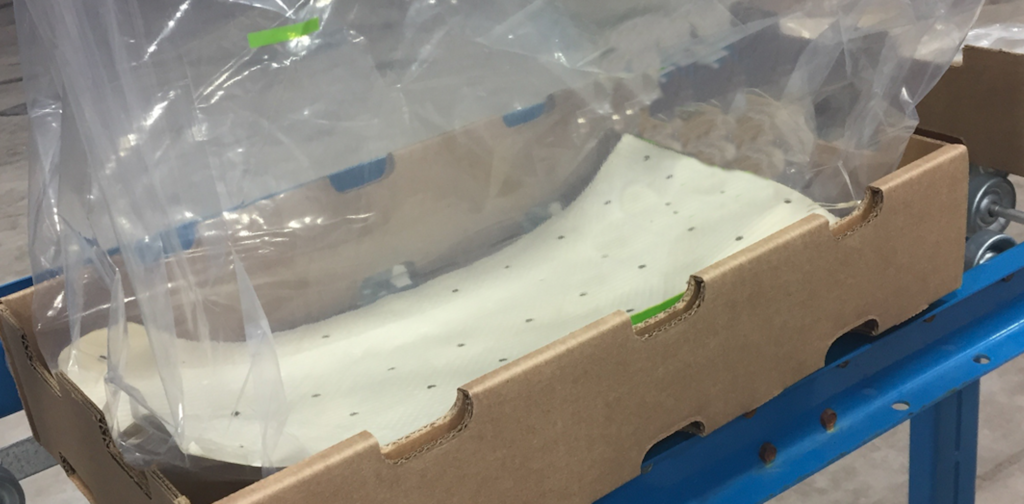

The length, width and height of the bag will depend on the box in which the fruit will be packed, as well as the sealing system to be used (automatic or manual sealing). From a practical point of view, the bag must cover all the internal spaces of the box; gusseted bags are generally used to meet this condition (Figure 1). To facilitate the packing and filling of the fruit in the boxes, especially in the case of cherries, where boxes are filled automatically, it is important that the bag can be folded outwards to be able to carry out this task.

- Bag thickness:

The thickness of the bag affects its sealing and its resistance to tearing and puncture. The bag must be able to be used and handled in all types of boxes (regardless of its composition) without risk of tearing or damage. On the other hand, the Chinese receiver prefers thicker bags (over 40 microns).

- Optical properties of the bag (brightness and transparency):

The bag should allow the fruit to be displayed, which is particularly important in the case of cherries, which are considered a gift and an expensive product.

Also related to the optics of the bag, when checking a box of cherries, the receiver checks to see if the bag is condensed or not and then touches the fruit through it to see if it is soft or firm.

For the last 5-6 years, some exporters, together with suppliers of this technology, have developed other MAP containers, the commercial results of which have been variable. With the aim of automating the packaging process, MAP thermoformed containers were developed using thermomolding technology for 5kg containers, but their commercial results were not as expected despite their impact on productivity, which resulted in a reduction in the number of personnel assigned to packaging and preparation of materials.

On the other hand, in order to avoid repackaging at the destination, and thus avoid food safety problems and facilitate online sales (e-commerce), heat-sealed containers have been developed that consist of rigid containers with a “lid” or upper film sheet through which the permeability of the container is adjusted. These formats have been worked from 500g to 2kg. The sheets that cover the containers can even be resealable (“reclose”). In this case, the other component of the container is a transparent clamshell treated with an anti-condensation additive and without vents. This type of container has been used for specific programs for supermarkets and its main limitation has been its productivity.

A challenge in the development of this technology has been the search for a system to prevent toxicity problems due to high levels of CO2 and low levels of O2 in the event of temperature changes. To this end, various tests have been carried out in which “intelligent” membranes have been tested that would have the capacity to adapt to the reality of our supply chain by modifying their permeability. Unfortunately, to date there is no commercial solution that meets these objectives.

We will surely continue to see more innovations in packaging and post-harvest technologies in the coming years that will allow us to improve our cherry offering.

Photo 1. 5kg MAP bag.

Figure 2. Thermoformed packaging for 5kg box

Figure 3. Thermoformed packaging

Figure 5. 500g MAP clamshell gas measurement.

used in technology validation.